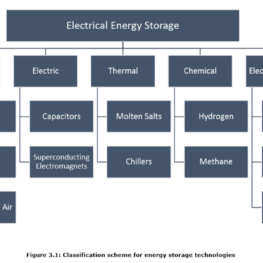

Presently, there are various energy storage technologies, including general descriptions of the technology, costs, and technological maturity. The broadest definition of energy storage includes any system for absorbing energy in some form at one time and releasing at a later time. Most such technologies convert electrical energy into another form for storage. Storage technologies can be grouped by the similarities of the interim storage medium.

Pumped Hydro Storage

Pumped hydro storage (pumped storage) is the most prevalent and mature energy storage technology, with 129 GW of installed capacity worldwide, 22 GW of which is in the US. Pumped storage is a very versatile technology capable of providing valuable benefits from intra-hour through multiple-day time periods. Pumped hydro stores energy by using electricity to pump water from a lower reservoir to an upper reservoir and recovering the energy by allowing the water to flow back through turbines to produce power. Pumped storage technology has a long economic life span typically more than 50 years, low O&M and lack of cycling degradation. Pumped hydro requires very specific siting requirements. Initial investment costs tend to be high. The 22 GW of installed capacity in the US has historically been used primarily as an energy management technology, ideal for load leveling and peak shaving.

Compressed Air Energy Storage (CAES)

In compressed air energy storage (CAES), energy is stored by running electric motors to compress air into enclosed volumes. The electrical energy is recreated when the stored compressed air is fed into the inlet of a combustion turbine. There are two utility-scale CAES systems in existence, the first built in Germany in 1978 (60 MW compressor, 321 MW generator, 4 hour discharge), and the Alabama Electric Cooperative McIntosh plant built in 1991 (50 MW compressor, 110 MW generator, 26 hour discharge).

Flywheels

Flywheels store electrical energy by speeding up inertial masses (rotors). Typically rotating masses rest on very low friction bearings (e.g., magnetic) in evacuated chambers designed to reduce friction as much as possible. Energy is transferred in and out using a motor-generator. Flywheels used for power applications range from 100 kW to 2 MW with discharge times from 5 seconds to 15 minutes. Energy storage flywheel modules store 0.5 to 1 kWh of energy.